Common FAQ | Doors | Trade Show Panels | Tiny House | Log Homes

General FAQ

Please feel free to shoot us an e-mail (contact us). If your question is not answered by our website or this FAQ page, we would be happy to further assist you!

How Do I Order Sing Honeycomb Panels?

Submit a Work Order by fax or email, and we will give you a quote within 24 hours. Our price is based on the quantity, length, width, thickness, and type of skin (choice of plywood, MDF, solid wood, aluminum, fiber glass, stainless steel, hardy planks, etc.). Your Sing Sandwich Panels have the Sing Honeycomb core sandwiched between two skins, enclosed with solid wood edging. All Sing panels are sold by price per square foot, so if you need strength, light weight and true flatness, Sing Sandwich Honeycomb Panels are the answer!

We make cut to size panels, posts and beams to build the smallest shelf to the largest door or you can even build an entire house (Click here to see an entire Sing Home build with Sing Honeycomb from foundation to roof within 3 days for the California home show in San Jose). All products can be ordered through our simple work order form. This includes panels for girdles, joisst, floors, walls, roof trusses, roofs, doors, window frames, kitchen cabinets, and countertops. Even our 100% collapsible dressers made of modular Sing honeycomb panels, posts and beams can be ordered by describing the length, width, and thickness you want to build your projects.

What Are Sing Honeycomb Panels?

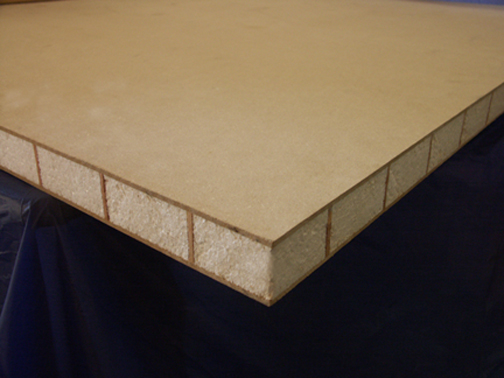

In the aircraft industry, they call it honeycomb. In the woodworking industry, it is called torsion box. In the home industry, it is known as sandwich panel. No matter what you call it, Sing Honeycomb Panels have the strongest, most lightweight earth friendly Sing Core to structure your Sing Panels. Sing Panel has more applications than any known material: use it for home construction, boat building, private jet furniture, home furniture, museum and trade show display, and doors. Patented Sing Panels are a hybrid of torsion box, sandwich, and honeycomb panel. It has the flatness of a torsion box, the strength of a honeycomb panel, and the light weight of a sandwich panel. Sing Panel combines all of these characteristics to form the most earth friendly panel in the industry.

What is the difference between your Sing Core, your Sing Core Panel & your Sing Honeycomb Panel?

A: See picture explanations below.

How can I build with my Sing Core and Sing Core Panels?

A: The different options of our Sing Core and Sing Core Panels allows you to decide how you want to work with our technologically

advanced core material. You can choose how much or little work you want to apply to the core*. (*when applying skins you will need to use a cold-press method)

Purchase just the core, you would then apply the skins on both sides and solid wood edging* (*place edging before apply top skin) or

Purchase core with skins* (*birch or luan) and apply the edge-banding or yourself or hire someone to do it or

Purchase the core as an all in one component* (core, skins (birch or luan) & solid wood edging)and receive your panels complete, just paint/seal and finish as you desire and install

|

|

|

|---|---|---|

Sing CoreHoneycomb Core which is based on Torsion Box technology to be lightweight but strong. You would then add skins and edging as you desire.

|

Sing Core PanelSing Core that has a skin on the front/back of it, which improves its strength and gives you a working palette for your project. You would then edge band as desired. |

Sing Honeycomb Panelis the complete panel |

How much do your Sing cores, Sing panels and Sing honeycomb panels cost? (Price Sheet)

Please email us your questions and we will respond within 1 business day.

I am a homeowner and I would like to use your product for my up coming project at home, how to I buy your products?

Dear Homeowner/DIY’er, unfortunately we do not sell to individuals, only to the building trades and commercial/wholesale companies. Please contact your local lumber yard and request that they order your panels for you and we will work with them to get you a great price.

Exactly how strong are your panels?

The strength of our panels depends on factors like span, thickness, and skin type. Our panels have reached up to 660 PSI.

What types of material can I laminate to honeycomb?

Any substrate (skin) that is capable of carrying a load.

How large a building do you need to start a Sing Products factory? 20-40,000 sq. ft.

What are the fire retardant qualities of our product?

Foam: level 2, Panel: untested

How well insulated are Sing Panels?

The R-Value of Sing Panels can be up to 6.5. Sing Honeycomb logs are up to R-35.

How do you ship?

LTL Freight Company - common carrier

Arrange for pickup by your preferred carrier

Customer pick up from our facility here in McCleary, Washington

What is your lead time?

Usually three to four weeks, but this has been know to extend out to five or more weeks on occasion. For our regular contract customers, we block out production time for them and for others we will “work with them” as our production schedule allows.

To whom do you sell doors?

We sell doors directly to businesses.

How do I seal the interlock?

It can be sealed with conventional caulking or waterproofing.

What is a torsion box?

A torsion box is best explained by this article.

( http://woodworking.com/ww/Article/What_is_a_Torsion_Box_8816.aspx )

What is a “board foot”?

12" x 12" x 1" = 1 Board Foot

12" x 12" x ½" = ½ Board Foot

12" x 12" x 2" = 2 Board Foot

Can I get sizes besides 4’ x 8’?

Yes, sizes smaller and larger are available, but you need to email us your custom sizes W x H x T and we will work with you to get a quote together.

We can manufacture panels up to 5’ x 10’. However, the most commonly ordered and most economical is our size 4’ x 8’* (*finished size is 47” x 95”) and that is because we’re usually limited by the size of the skins available and whether you can smooth out the seams between skins for larger sizes. Sizes are also limited by shipping company restrictions.

How much pressure to I use to apply skins myself?

Enough for intimate contact with our honeycomb core with or without solid wood edging but too much pressure can cause damage to the core.

Do you have distributors?

No, at this time everything is sold directly by us from our manufacturing location in McCleary, Washington.

What do you keep in stock?

All of our Sing Cores, Sing Core Panels, & Sing Honeycomb Panels are made to order for each of our customers.

What is the weight of your panels?

The weight of our panels are based on many factors, W x H x T, the types and thickness of the skins chosen and of course the solid wood edging as well. But for a rough ballpark estimate the weight of one of our standard panels 4’ x 8’ x 1” (finished size = 47” x 95” x1”) is somewhere in the 25 to 30 lbs range, which is much lighter than standard plywood of the same size/thickness.

What does paint grade not paint ready mean?

We deliver your panels as paint grade as opposed to paint ready, due to several instances where our definition of paint ready did NOT meet our customer’s definition of paint ready. Because of these issues, we now leave it up to the customer to get their panels to their preferred finished state.

What are the days and hours you are open?

We are generally in the office between 9 a.m. to 4 p.m.

Monday –Friday (Pacific Time) except for federal holidays.

Lunch is between 12 - 12:30 pm.

Isn’t Lauan difficult to work with?

Our Lauan is in the form of veneer, so the natural fragility of the wood isn’t a factor.

How do you fasten panels?

Fasten your panels with dowel, bolts, biscuit, camlock (rotorlock), or edge to edge glue. Visit our Fastening Page for details.

How fast can you produce panels? We can produce hundreds of panels each day.

Where do you distribute?

We currently serve the United States and Canada.

What kind of wood do you use for solid wood edging?

We use soft wood because it’s easy to control the moisture content and to fasten. Soft wood also weighs less than solid hardwood.

What if you use a basic interior door as an exterior door?

It’ll bend because moisture will get inside the door and press outward on the skin. We don’t guarantee for weather exposure because we don’t control how you treat the surface. If treated properly with urethane, your doors can withstand the weather.